Create Your Device

Our Systematic Approaches

We work with minds

By working closely with our customers, we can identify market demands and gather innovative ideas that drive our product development. We’re very good at combining the innovative mechanical structure and our engineering knowledge + greatest idea of our customer, so products from us usually stand out of market in a very short time.

Feasibility Study

Once we received your request, we audit the feasibility of your idea, and allocate resources to help you succeed.

Industrial Design

Streamlines, curves, complicated structures, we design elegant products that highly loved by people from everywhere.

Electrical Engineering

We create detailed schematics and circuit designs to ensure reliability and seamless integration of electrical components.

Mold Production

Our mold center is national-class, we select appropriate materials and design the mold to meet precise specifications, considering factors such as parting lines, draft angles, and cooling systems.

Pilot Production

Initiate a small batch of products using finalized designs and processes. This allows us to test and validate the manufacturing workflow, identify and resolve any issues, and ensure quality standards.

Mass Production

We conduct mass production using optimized processes. Our focus is on maintaining high standards and meeting delivery timelines effectively.

Your projects are alway safe with us and well-regulated. We use clinical-proven technologies and our products are developed under medical device regulation ISO13485 and GMP.

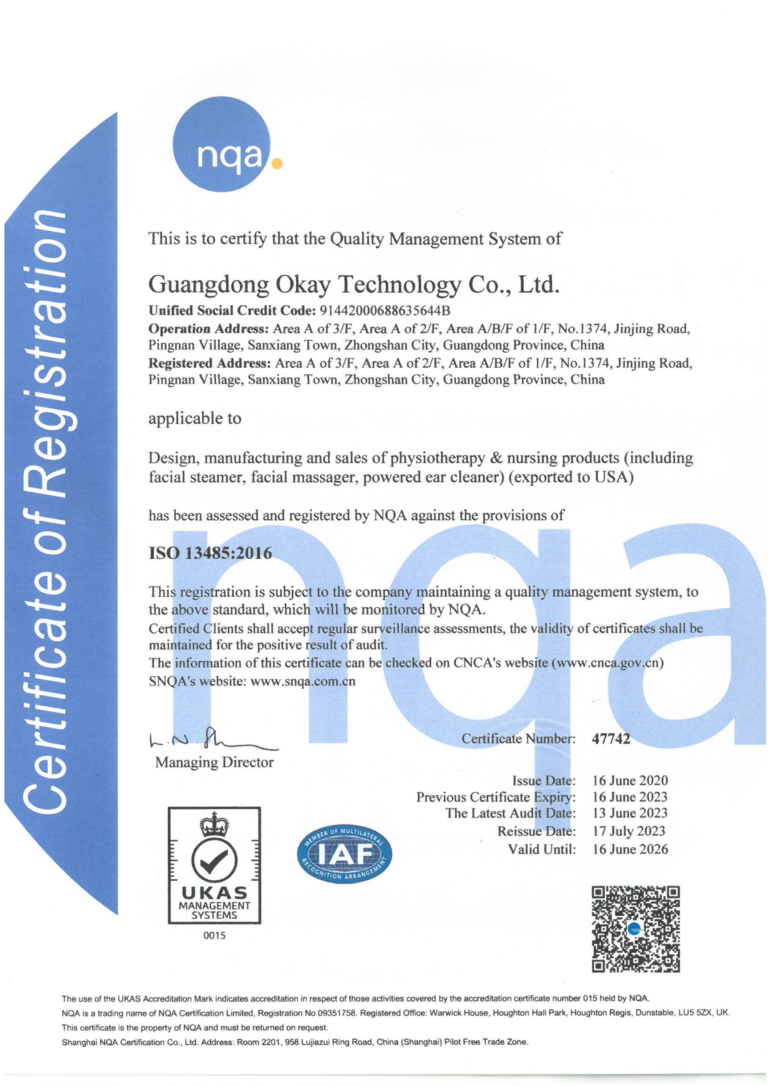

ISO13485

ISO 13485 is an international standard that specifies requirements for a quality management system (QMS) specific to the medical devices industry.

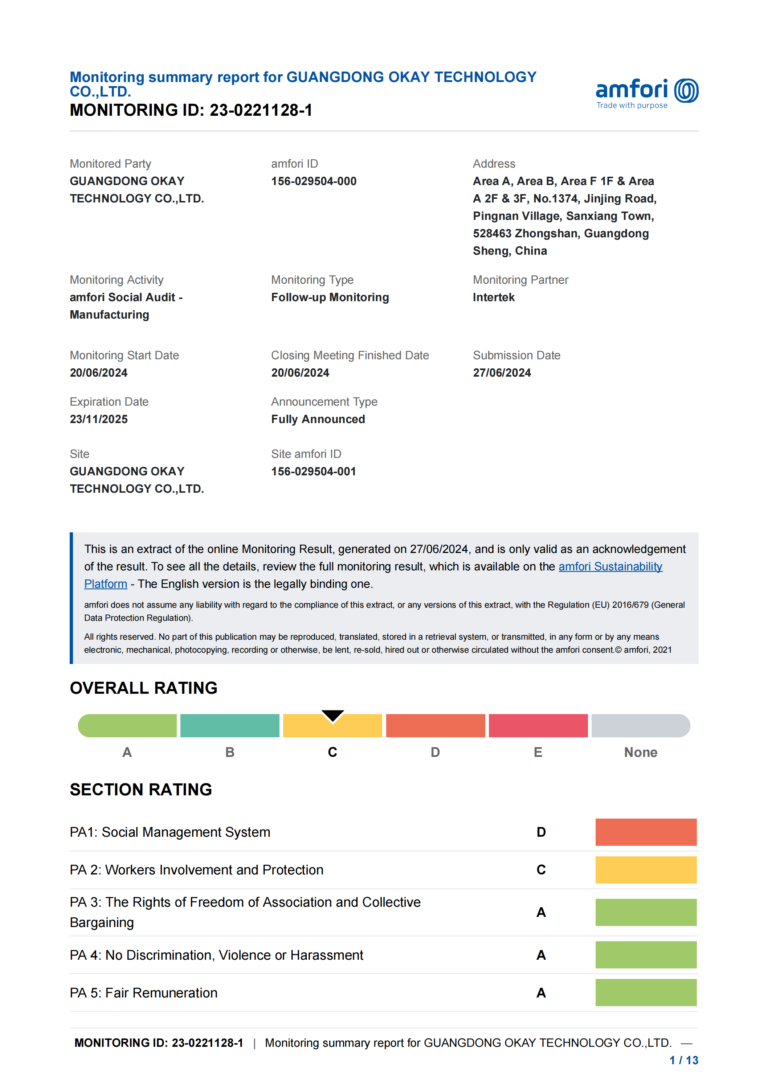

BSCI

BSCI stands for a global supply chain and company audit called Business Social Compliance Initiative. BSCI provides companies with a systematic approach to improve their working ethicacy.

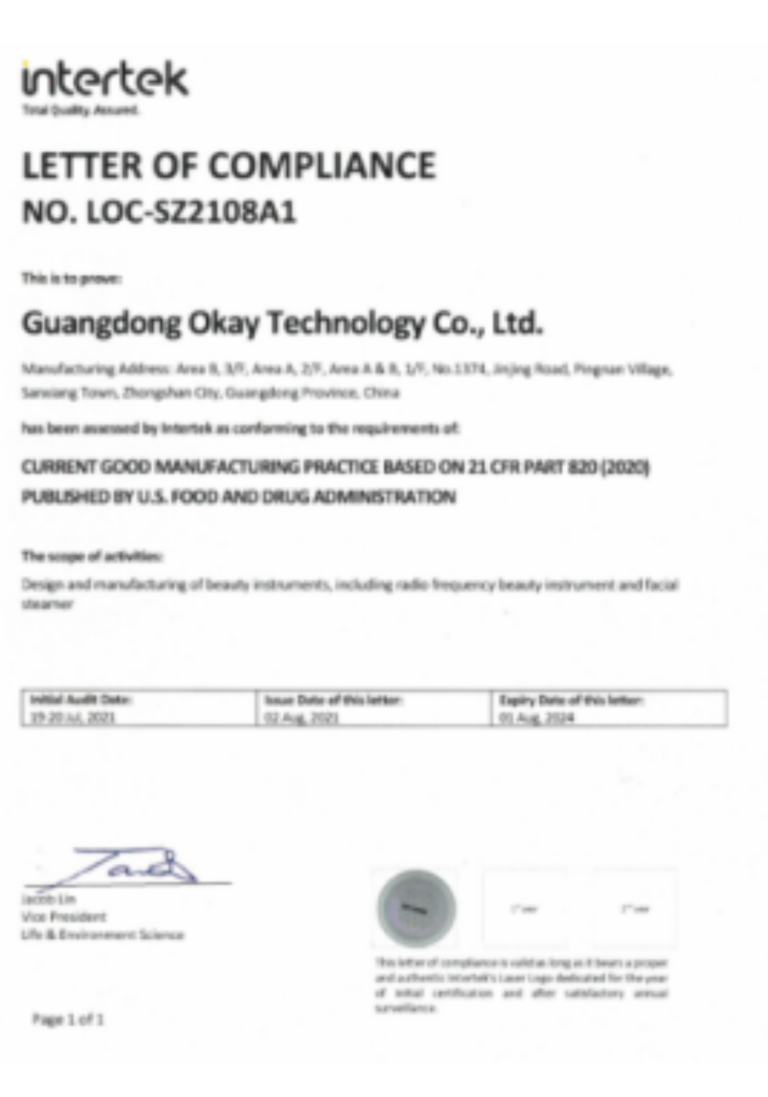

GMP QSR-820

GMP QSR-820 refers to the Good Manufacturing Practice (GMP) Quality System Regulation (QSR) Part 820. This is a medical devices regulation enforced by the U.S. Food and Drug Administration (FDA)

ISO14001

ISO 14001 is an environmental quality control. The standard is designed to help organizations systematically reduce their environmental impact, improve resource efficiency, and reduce waste.

ISO9001

ISO 9001 is an international standard that specifies requirements for a quality management system (QMS). Organizations use the standard to demonstrate their ability to consistently provide products and services that meet customer and regulatory requirements

Product 0-1

ID Design

In order to fit a intricate structural and electronic components into the small body, ID Design took carefully work to develop and debug, from sketches, modeling, structural stacking, CMF to prototypes.

Energy Simulation + Molding

In a very short period of time, our R&D engineers worked out dozens of solutions in different directions. Through thermal field simulation experiments, electrode arrangement verification, energy simulation and other workflows, we found the perfect answer in our minds – the most effective product.

assemble & Test

A precision beauty device may consist of dozens of parts. We assemble it as quickly as possible and conduct strict quality inspections through up to 40 testing procedures.

ID Design

The finished beauty device must consider both functionality and high performance at the same time, and more importantly, consider safety, manufacturability and comfort.

Streamlines, curves, complicated structures, we design elegant products that highly loved by people from everywhere.

In order to fit a intricate structural and electronic components into the small body, ID Design took carefully work to develop and debug, from sketches, modeling, structural stacking, CMF to prototypes.

Energy Simulation + Molding

Whether electricity, RF or light energy level will be tested under clinical standard and regulation of ISO13485 and GMP.

In our top-tier mold center, we use multi-axis CNC machines to make integrated-molding case. After milling, fine carving, mirror polishing and other more than 40 processes of fine grinding, and careful polishing by engineers, with a tolerance less than 0.01mm, we have a body shell with such a delicate touch and outstanding hand feel.

Assemble & Test

Design, Electrical Engineering, Molding, Assembly etc are all done under a roof.

Our integrated in-house manufacturing ensure qualified products can be delivered in a short period.

Assemble & Test

Our assembly process starts with meticulously organized workstations and skilled technicians who follow detailed assembly guidelines. We begin by gathering all necessary components and conducting a quality check to ensure they meet our standards. Our process is designed to be efficient, minimizing waste and maximizing productivity, while maintaining the highest standards of quality and reliability.

Assemble & Test

A device will be delivered after more than 30 testings, for example we’ll test: Drop Test; Environmental Temperature; Chemical Resistance; Corrosion; Allergy; Irritation; Cable & Button Life; Noise; Irradiance; Light & Electricity Energy

We ensure products from us are with premium level quality and best endurance.

FAQ

How can I work with you?

Before each project begins, we discuss with our client for their specific approach to succeed. From concept ideation to final delivery, we facilitate every stage of product success.

What's the average lead time?

For samples, the delivery time is approximately 7 days. For mass production, delivery time is 45 days after receipt of deposit. These delivery times begin after we receive your deposit and final product approval. If these schedules do not align with your deadlines, please discuss your requirements with your sales representative. We will make every effort to meet your needs, and in most cases we are able to do just that.

Payment Method accepted?

Wire transfer (T/T) is the most accepted method of payment. Or in other cases, we accept L/C (letters of credit). If you need more payment terms, please feel free to contact our sales rep.

I concern about Intellectual property.

From Fortune 500 companies to those fast-emerging names, our partners will be having fully control to the project with us.

Secret materials like product designs, drawings and molds etc are all created in our fully-owned plant, also we’ll sign a NDA (Non-Disclosure Agreement) with you before the engagement begins.

Do you support OEM / ODM?

Yes, we support OEM/ODM, you can sell some of our products with a slight modification like logo. Please contact the sales team and one of our sales rep will send you a catalogue pretty soon.

Warranty policy?

Our current warranty is one year from the date the product leaves the warehouse. We stand by quality of materials and exquisite craftsmanship. No matter in warranty period or not, we are happy to make sure everyone is satisfied within the cooperation.

Can I order a sample?

Yes please reach out to our sales team for the access of samples.

Is it possible to visit your company?

In our DNA and company culture, whoever comes is our valued guest. You can choose to visit our company virtually from the homepage or ask for a visit any time. ❤ ️